Current sensors are necessary for instrumentation as well as power systems. This is because it is essential to measure the current that is flowing through systems without having a detrimental impact on their performance.

Throughout human history, the protection and management of electrical circuits have been the primary tasks of current sensing. Nevertheless, as a result of technological improvements, current sensing has evolved into a technique that may be utilized to examine and improve performance.

It is possible to determine the amount of current that is flowing to a load, which is a skill that is incredibly valuable in a wide variety of applications. Before delving further into their capabilities and applications, this article provides a high-level overview of the many sensors that are now available.

Current Sensors

A current sensor is a piece of equipment that can measure current and then change the measured current into a voltage that can be readily measured. The quantity of voltage that is being output is exactly proportional to the amount of current that is passing through the channel that is being monitored.

This voltage signal is then used for control reasons, stored for further analysis in a system that collects data, or displayed on an ammeter to display the measured current to provide feedback to the user. All of these processes take place after the signal is collected.

A current sensor's principal function is to carry out the operation of translating current into voltage to be used in various settings. This information can then be utilized in a variety of ways.

Current Sensor Variety

One can purchase a broad variety of sensors on the market, each designed for a specific range of current and particular environmental circumstances. The AC current sensor is the one that is utilized as a current-to-voltage converter the vast majority of the time among these many sensors.

This is accomplished by including a resistor on the path that the current takes, which enables the current to be linearly converted into voltage and therefore accomplishes the goal. The selection of the technology that is utilized in these sensors is of the utmost significance due to the fact that different kinds of sensors each offer individual attributes that are optimized for specific purposes.

Current Sensor Working Principle

Direct and indirect current sensing are the two fundamental methods that are involved in the operation of the working principle of a current sensor. Direct current sensing is the more common of the two.

Direct Current Sensing

Direct current sensing is a method that makes use of Ohm's law to calculate the voltage drop that is associated with the flow of direct current via passive electrical components. This is accomplished through the utilization of a technique known as direct current sensing.

Indirect Current Sensing

Sensing of the Indirect Current On the other hand, Ampere's and Faraday's laws are necessary for the operation of indirect sensing in order for it to work properly. It is a piece of equipment that measures the magnetic field that is produced all around a conductor when that conductor is in the process of conducting a current.

This magnetic field is then utilized to generate a proportionate current or voltage, which can afterward act as the foundation for additional applications such as measurement or control.

Capacitive Current Sensor Specification

The present specifications for a sensor specify both the operational mode of the sensor as well as the manner in which it engages with the environment that it was created for. The following is a list of some of the most essential qualities that should be included in a current sensor:

Measuring Range

The Sensing Range refers to the maximum amount of amperage that the sensor is capable of sensing, which is often up to 120A. In most cases, the measuring range is 120A.

Input Voltage

The voltage that must be present in order to turn the device on, is commonly +5V and can also be written as "Input Voltage."

Frequency Range

The frequency range of a sensor is referred to as the frequency range, and it typically varies from 20 hertz (Hz) to 20 kilohertz (kHz).

Response Time

The amount of time that passes between when an input stimulus is applied and when the corresponding output signal is produced is referred to as the system's response time. The duration of this time gap is often less than 20 nanoseconds.

Isolation Voltage

The term "Isolation Voltage" refers to the highest voltage that the sensor is able to withstand in order to protect devices that are attached to it. This is done in order to keep the devices from being damaged. If you go outside of this range, you run the danger of harming the current sensor, which will result in inaccurate readings. If you go outside of this range, you run the risk of damaging the current sensor.

Accuracy

The precision of the current sensor, which in most cases is greater than 90%, is what's meant when people talk about accuracy.

Types of Current Sensors

Today's sensors can be wireless, analog, or digital; each type satisfies a different set of requirements in its own particular way, and there are many various kinds of sensors accessible.

These sensors are put to use in a diverse range of applications in order to carry out continuous monitoring of the current values in a number of appliances and pieces of machinery. The following are the key categories that are available:

Shunt Resistor:

Shunt resistors are a type of sensor that is utilized for the purpose of determining the presence of DC current. These sensors produce voltage when current runs through a resistor because the voltage is produced across the resistance.

Although they have benefits like as low cost, rapid response, and high accuracy, they do not have electrical isolation from the current that is being measured, which is a disadvantage. Despite these benefits, they do not have this advantage, which is a disadvantage.

Hall Effect Current Sensors:

These Hall effect current sensor are capable of monitoring alternating current (AC) and direct current (DC) currents at frequencies up to one hundred kilohertz.

They operate according to the concept of the Hall Effect, which results in good isolation and remarkable precision; nevertheless, their response time is substantially longer than average, and their accuracy while measuring small currents is significantly lower.

Current Transformer:

These sensors are able to turn massive currents into tiny currents for the purposes of measurement and protection by employing the principles of electromagnetic induction, which is the underlying technology of the current transformer. They have a closed iron core as well as windings, all of which contribute to the product's excellent precision and isolation capabilities.

Flux Gate Current Sensor:

In order to detect currents ranging from 6 to 600A, these sensors make use of a magnetic balance mechanism. The scientific name for these sensors is flux gate current sensors. They are ideally suited for high-precision measurements in a wide variety of equipment, including industrial and medical devices.

Current Sensors Circuit Diagram:

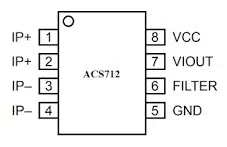

The following is a diagram of the circuit for the Current Sensor:

Current sensor circuits, such as the one that utilizes the ACS712 integrated circuit, are used in a range of applications for the purpose of measuring current. These circuits are used to determine how much current is flowing through a certain device.

The ACS712 integrated circuit is a Hall Effect current sensor that can measure currents of up to 20A and is available at a price that is not excessively high. The architecture of the circuit incorporates terminals for the power supply, for monitoring the current, and for providing an output signal. Using a microcontroller such as Arduino, one is able to do tasks including the processing of real-time data and the display of said data.

Current Sensor Arduino

By connecting a current sensor to an Arduino board, it is possible to acquire an accurate reading of the current flowing through the circuit. The ACS712 current sensor is able to perform accurate measurements of both direct and alternating currents. The interface needs to be set up with a power supply, load, an ACS712 current sensor, an Arduino Uno board, an LCD display, a potentiometer, resistors, and connecting wires.

The Arduino programming code

The analog data obtained from the current sensor is processed with the Arduino code that has been provided, and the results of this processing are then displayed on an LCD display as the value of the current. The sensitivity of the sensor and the offset voltage are taken into consideration when calculating the amount of current that should be flowing.

Testing Arduino Code

In order to ensure that the results are reliable, testing the current sensors is absolutely necessary. It lends a hand in monitoring and adjusting the flow of current to devices, which helps to make sure that the devices get the right amount of current. Accurate sensors are required not only for the efficient operation of machinery but also for the protection of its users.

Benefits and Drawbacks

Current sensors have a number of features, such as low heat generation, a wide measuring range, an extended bandwidth, high resolution, precision, and a low offset. In addition, current sensors have a relatively low measuring error.

However, they do have a few drawbacks, such as a higher heat generation rate, a limited ability to measure large currents, a low hall element sensitivity, an incompatibility with non-conductive materials, and a sensitivity to changes in temperature. Additionally, they are incompatible with materials that are not conductive.

Current Applications for Various Types of Sensors

Current sensors are helpful in a wide variety of contexts, including power metering, the measurement of current supplies, the diagnosis of control systems, load control in motors, charge integration, battery condition monitoring, facility management, sub-metering, fault detection in machinery, and commercial appliance protection against surges. These are just some of the applications where current sensors are useful.

Conclusion

In a nutshell, current sensors are an essential part of the process of measuring and monitoring current in a wide variety of different applications since they are an integral component. They can be obtained in a variety of forms, each of which is distinguished from the others by a unique collection of traits and advantages.

In order to maintain the reliability of electrical systems and ensure proper current flow, current sensors are a vital component that must be used. The management of power and the safeguarding of apparatus are also possible applications for these sensors.

You Might Also Like: Why PTVS1-xxxC-H Series TVS Diodes Are Essential for Circuit Protection