In modern engineering, innovations constantly chase efficiency and accuracy in every field. The Hall effect DC Sensor is one of the most groundbreaking inventions of this digital age. This resourceful device has emerged in measuring current, offering unparalleled precision and reliability in various applications.

This article will delve into the Hall Effect sensor's intricacies, exploring its operation principle, advantages, applications, and significance in modern electronics.

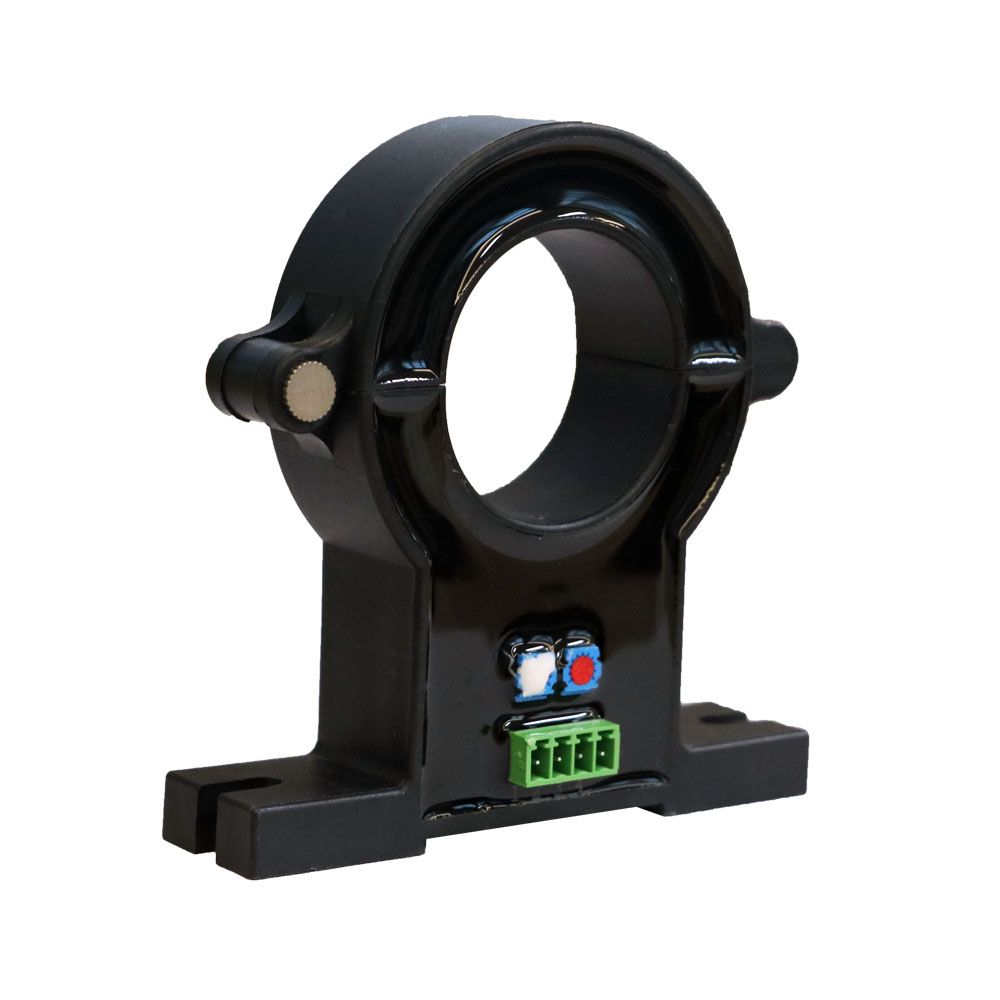

Hall Effect Sensor

Hall Effect sensors are very sophisticated devices that are used to monitor current. Based on the Hall Effect, which is a phenomenon that happens in a conductor when it is exposed to a magnetic field while carrying an electric current, these sensors work. Numerous industries have adopted the cutting-edge approach for measuring current, which has increased operational effectiveness and safety precautions.

Principle of Hall Effect

The basic tenet of the Hall Effect concept is that a voltage differential forms across a conductor with a current running through it when subjected to a perpendicular magnetic field. The Hall voltage is directly related to the magnetic field's current and intensity. This provides the foundation for precise current measurement using Hall Effect sensors.

Working Mechanism

Three essential parts comprise a standard Hall Effect DC Current Sensor: the Hall element, the magnetic circuit, and the signal processing circuit. When exposed to a magnetic field, the Hall element generates the Hall voltage, typically a thin semiconductor material. While the signal conditioning circuit processes the Hall voltage to generate an output signal corresponding to the measured current, the magnetic circuit ensures the magnetic field is aligned adequately through the DC power meter.

Contribution of Hall Effect Sensors to Improve Efficiency

Hall Effect sensors provide precise and real-time current readings, which improves efficiency. This knowledge allows intelligent control systems to improve energy use and reduce waste. These sensors ensure the accurate functioning of equipment in industrial environments, minimizing downtime and maintenance expenses.

Applications

Hall Effect DC Current Sensors' uses in various sectors demonstrate their adaptability. These sensors are essential for monitoring and managing power use in energy management systems.

They are essential for electric cars that provide effective motor and battery control. Hall Effect sensors are also used in telecommunications, aircraft, and industrial automation for precise current sensing.

Advantages

Comparing Hall Effect sensors to conventional current measuring methods reveals numerous clear benefits. They do not need physical contact with the conductor carrying the current since they are non-intrusive.

The likelihood of electrical mishaps is reduced by this feature, which also improves safety. Hall Effect sensors also provide galvanic isolation, which qualifies them for high-voltage applications.

Fight Noise and Accuracy Issues

Hall Effect sensors are often insulated and furnished with signal conditioning circuits to address noise-related problems. Even in loud surroundings, these circuits provide precise readings by filtering out undesirable signals. Calibration and compensating techniques are also used to mitigate the impacts of temperature changes.

Challenges

Hall Effect sensors have temperature changes and noise interference issues despite its benefits. Thermal drift and external magnetic fields may impact measurements' precision. However, these restrictions are still being addressed thanks to developments in sensor technology and signal processing methods.

Future of Hall Effect Sensing

The future of Hall Effect sensors promises intriguing possibilities as technology advances. Future developments will enable real-time data collecting and remote monitoring via miniaturization and integration with IoT devices. These developments will expand the sensor's potential uses and aid in creating smarter systems.

Energy Management Systems

Hall Effect DC is a kind of energy management. Current sensors are essential for preserving effectiveness and minimizing waste. These sensors allow the optimization of power distribution and support sustainable energy practices by precisely monitoring current use.

Automotive Technology Integration

Hall Effect sensors have found widespread use in the automobile sector for several applications, including motor control, battery monitoring, and safety systems. These sensors offer accurate propulsion system management in electric and hybrid cars, improving overall vehicle performance.

Industrial Equipment Enhancement

Hall Effect sensors have transformed industrial equipment safety procedures. These sensors keep track of current levels in equipment and systems to identify irregularities and activate shutdown procedures, averting accidents and guaranteeing operator safety.

Comparison with Other Current Measurement Techniques

The benefits of Hall Effect sensors become clear when contrasting them with conventional current measuring methods like shunt resistors and Rogowski coils. They are an excellent option for many applications because of their precision, galvanic isolation, and non-contact measuring capabilities.

Conclusion

In conclusion, a new age of precision and efficacy in current measurement has arrived thanks to the Hall Effect DC Current Sensor, by delivering trustworthy, real-time data for insightful decision-making.

This sensor, whose concept is firmly founded in the Hall Effect phenomenon, has revolutionized several sectors. We may anticipate more developments and uses for this incredible gadget as technology progresses.

You Might Also Like: Supervisory Control & Data Acquisition (SCADA)

Craving more information, contact Aim Dynamics today