Rogowski Coils for Current Sensing

In the realm of electrical engineering and power monitoring, Rogowski coils have become increasingly popular. These flexible, coil-shaped sensors offer a versatile and accurate solution for current sensing. They possess several advantages, including the ability to measure AC and DC currents without intrusion.

However, like any technological advancement, there are common mistakes that can result in inaccurate readings or operational issues when utilizing Rogowski coils for current sensing purposes. In this article, we will delve into these potential pitfalls and provide valuable insights on how to navigate around them.

Introduction

Before we delve into the common mistakes associated with Rogowski coils, it's essential to provide a brief introduction to these current sensors and grasp their significance across various applications.

Rogowski coils are versatile current sensors with a toroidal and flexible structure, eliminating the need for a magnetic core. These coils find wide application in various fields such as power quality monitoring, energy management, and electrical fault detection. Engineers often favor their non-intrusive design as it allows easy wrapping around conductors without disrupting the electrical circuit.

Not Understanding Rogowski Coil Basics

One common mistake with Rogowski coils is the lack of understanding regarding their fundamental principles. It is important for users to grasp how the coil's geometry, turns, and materials impact its performance. Failure to comprehend these basics can result in data misinterpretation.

Neglecting Proper Coil Sizing

Selecting the appropriate Rogowski coil size is of utmost importance. If the coil is too small, it may not provide accurate readings, whereas saturation can occur if it is too large. Engineers should take into consideration both the conductor's diameter and current range in order to ensure precise measurements.

Incorrect Placement and Orientation

Improper placement or orientation of Rogowski coils may lead to distorted measurements. It is crucial to ensure that the coil is positioned correctly around the conductor and aligned with the current sensor flow. Explanation: The improved version maintains a neutral and objective tone while using clear and concise language. The sentence has been divided into two shorter sentences, adhering to Hemingway's guideline of breaking

Disregarding Calibration

Skipping calibration procedures is a surefire way to introduce inaccuracies into your measurements. In order to maintain precision, Rogowski coils must undergo regular calibration. Failing to prioritize this crucial step can lead to the generation of faulty data.

Ignoring Environmental Factors

Engineers must consider various environmental conditions, such as temperature, humidity, and electromagnetic interference. These factors can significantly influence the performance of Rogowski coils. To ensure accurate measurements, it is essential to assess these variables carefully and select appropriate sensors accordingly.

Overlooking Signal Conditioning

Inadequate signal conditioning has the potential to introduce unwanted noise and errors into the measurements. To ensure reliable data, it is crucial to employ proper conditioning circuits and filters.

Neglecting Cable Length and Routing

When connecting the Rogowski coil to Power monitoring equipment, it is essential to consider the length and routing of the cables. Excessive cable length can lead to additional resistance and capacitance, affecting the signal's accuracy.

Failing to Consider Frequency Range

Different Rogowski coils have specific frequency response ranges. Users should ensure that the coil's frequency range matches the requirements of their application to prevent distortion from occurring at higher frequencies.

Lack of Grounding

Proper grounding plays a crucial role in ensuring accurate measurements. Neglecting to establish proper grounding can result in issues with common-mode voltage and lead to inaccurate readings.

Not Using Shielded Cables

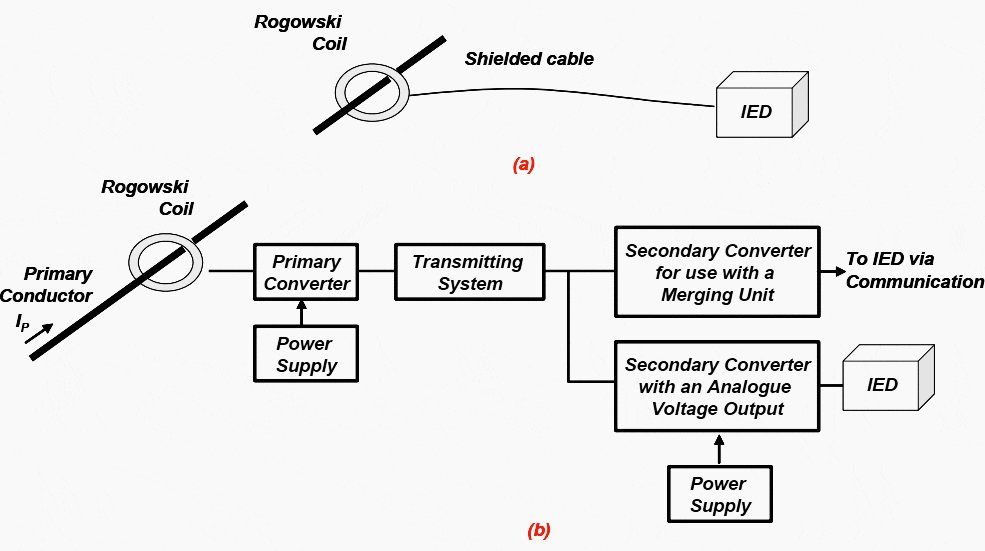

Using unshielded cables can make Rogowski coils vulnerable to electromagnetic interference. To minimize external influences on measurements, it is advisable to employ shielded cables.

Poor Installation Practices

Rogowski coils should be installed carefully, taking into account insulation and secure placement. Neglecting these steps could result in safety risks and inaccurate measurements.

Forgetting to Verify Data Accuracy

Users frequently overlook the importance of verifying the accuracy of their measurements. It is crucial to regularly compare and cross-check measurements with other methods or instruments to promptly detect any inconsistencies or discrepancies.

Skipping Regular Maintenance

The long-term reliability of Rogowski coils heavily relies on regular maintenance, which includes essential tasks like cleaning and inspection. The neglecting of proper maintenance practices can gradually deteriorate the performance of the coil over time.

FAQs

1) Can Rogowski coils be used in high-frequency applications?

When selecting a coil, it is crucial to ensure that its frequency response range aligns with the specific requirements of the application.

2) Can Rogowski coils be used in outdoor environments?

In considering the well-being of coils, it is essential to account for environmental factors like temperature and humidity. Providing appropriate protection under such circumstances becomes crucial.

Conclusion

In various applications, Rogowski coils serve as valuable tools for current sensing. However, in order to ensure accurate and reliable measurements, users need to be aware of common mistakes. To avoid errors in your current sensing tasks, it is crucial to understand the basics of the coil, properly size it, install it correctly, and perform regular maintenance.

You Might Also Like: What is Celsius to Fahrenheit: How to Convert and Why it Matters