Stepper motors are widely used for precise control and positioning capabilities in various industries. A stepper motor controller is necessary to utilize a stepper motor to its maximum capacity. In this blog, we will examine the inner workings of stepper motor controllers, how they function, and how they enhance the effectiveness of stepper motor systems.

What is a Stepper Motor Controller?

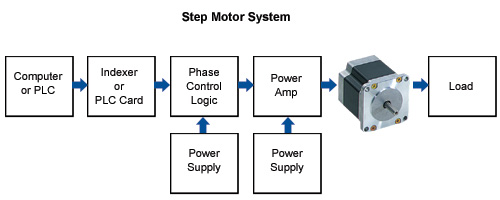

A stepper motor controller turns digital waves into mechanical movement. It sits between the stepper motor and the control system and ensures that the motor is properly placed and controlled. By sending a series of pulses to the motor, the controller can move it exactly in discrete steps, making it perfect for applications that need to be placed precisely.

Stepper Motor Controller Work

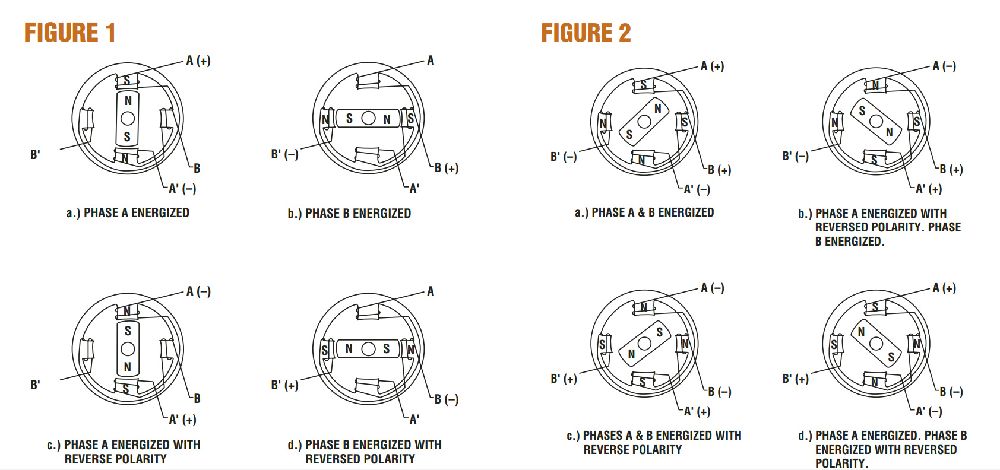

To make a stepper motor driver work, electrical pulses are sent to the motor windings in a particular order. If this sequence is followed, the motor will move this way and for this distance. The processor makes these pulses based on what it gets from the control system, such as a computer, PLC, or microcontroller.

One important thing about stepper motor drivers is that they let you change the motor's speed and acceleration. The controller can change the speed of the motor's rotation and acceleration by changing the pulses' frequency and timing, allowing smooth and accurate movement.

Benefits of Stepper Motor Control Systems

Stepper motor controllers have several benefits, such as:

- Precise Positioning: When stepper motors are combined with controllers, they can precisely place things. This makes them perfect for situations where accuracy is critical.

- Open-Loop Control: Other types of motors need feedback systems to be controlled, but stepper motors can work in an open-loop system with processors' help, making control easier.

- Budget-Friendly: Stepper motor controllers are cheap options for tasks that need exact control but don't need complicated feedback systems.

Conclusion

Stepper motor controllers are essential to working stepper motors because they allow precise positioning and control in many situations. For stepper motor systems to work as well as possible, you must know how these controls work.

You Might Also Like: Understanding Current Transformer Accuracy Classes Under IEC 61869-2