Aim Dynamics primarily sells current sensors for the purpose of power monitoring. Current sensors, when connected to the right device enable the measurement and monitoring of electrical currents flowing through equipment, machinery, and power systems. This information can be utilized to maintain optimal performance, identify abnormalities, and ensure safe and efficient operation. When companies can accurately measure current levels using Hall effect sensors, companies can monitor power consumption, detect malfunctions, prevent overheating, and reduce the chance of issues caused by power issues.

Smart Products and Effect Sensors

Smart products using current sensors can collect and analyze data in real time. This ability can help businesses to identify and address possible issues in their processes. A potential result of these monitoring devices is the ability for companies to make significant improvements in productivity and cost savings. For example, smart sensors can be used to monitor the performance of machinery and equipment and to identify potential problems before they cause a breakdown. This alone helps to minimize downtime or improve the efficiency of a production line.

Thermal management goes hand in hand with electrical efficiency. Inverter motors and other systems operate more efficiently at low temperatures than at high, so a smart sensor that manages heat more efficiently than a traditional bimetallic thermostat is a huge benefit to both reliability and safety. With more responsiveness to changes in thermal performance and regulation of temperature, the thermal management systems can be made smaller and more energy-efficient, freeing up space that was traditionally used for thermal management to handle higher-performance electronics.

Cars and other vehicles are a prime opportunity for heat management as well, with automotive temperatures using traditional systems reaching temperatures as high as 150 degrees Celsius depending on where the electronics are mounted within and around the engine, according to Texas Instruments. Mitigating this is the fact that automobiles operate in an environment with constant air cooling, reducing the heat stress on systems. Current sensors, however, are more useful in these areas than bimetallic thermostats since they can measure heat independent of air flowing over them and can be made smaller and lighter.

Precision Feedback

With performance paramount, Hall effect current sensors create one of the most important means of monitoring and feedback to electronic devices available. With the current sensor, you’re not dependent on slower means of systematic feedback, like software monitoring. The performance of the electronic circuit for a given power input will control how well that circuit performs, ultimately, in its needed functions. Current-sensing technology makes it cost-effective to monitor the performance of your circuits in real-time, not just on the test stand but in real-world performance metrics. There are two types of Hall effect current sensors: Open-loop and closed-loop. The former is less accurate, but they are also less expensive and require less power to operate. A closed-loop sensor is more precise, accurate, and quick. Both have their advantages in the field. The test stand always favors closed-loop systems, but the real world tends to flatten their differences. Some resistors are better for bidirectional current and some for unidirectional current. In both cases, the right option will present itself from the available choices.

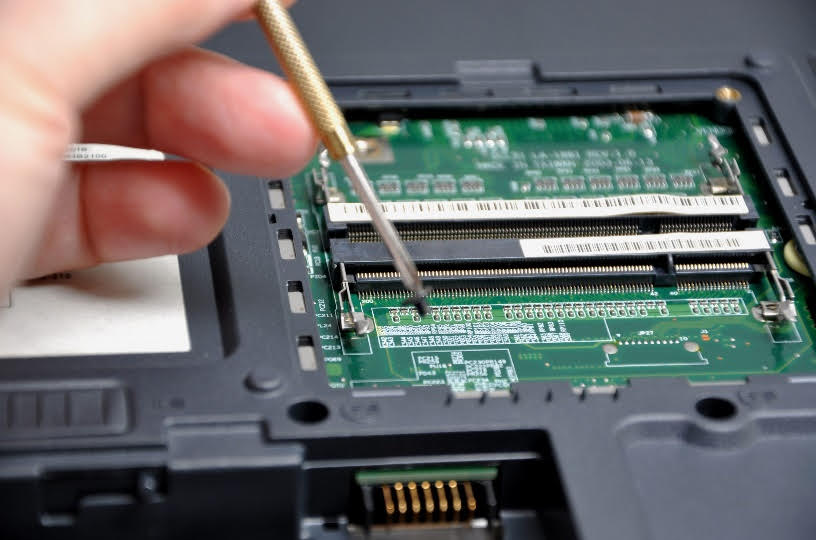

Current and temperature sensors have wide applicability in the electronics industry.

Looking to learn more? Contact us today at Aim Dynamics!