TELE power monitoring systems offer significant advantages, particularly in situations in which monitoring tasks are usually carried out by sensors:

- No problems due to contamination and any decalibration of the sensors

- No maintenance and cleaning costs

- Easy to use, even in charged air or volatile substances

- Savings in terms of cabling

- No use of explosion-proof barriers necessary

- Reduction in error sources

- Simple retrofitting

Current Monitoring Relays: Pure current measurements in the supply to motors can only be used in an extremely restricted capacity to monitor loads. This is due to three essential factors:

- In alternating current circuits, the measured current is apparent current. This total current comprises the sum of reactive and active current components. However, when generating mechanical power it is the active current that is exclusively decisive. The reactive current merely causes losses and does not contribute to the shaft power delivered.

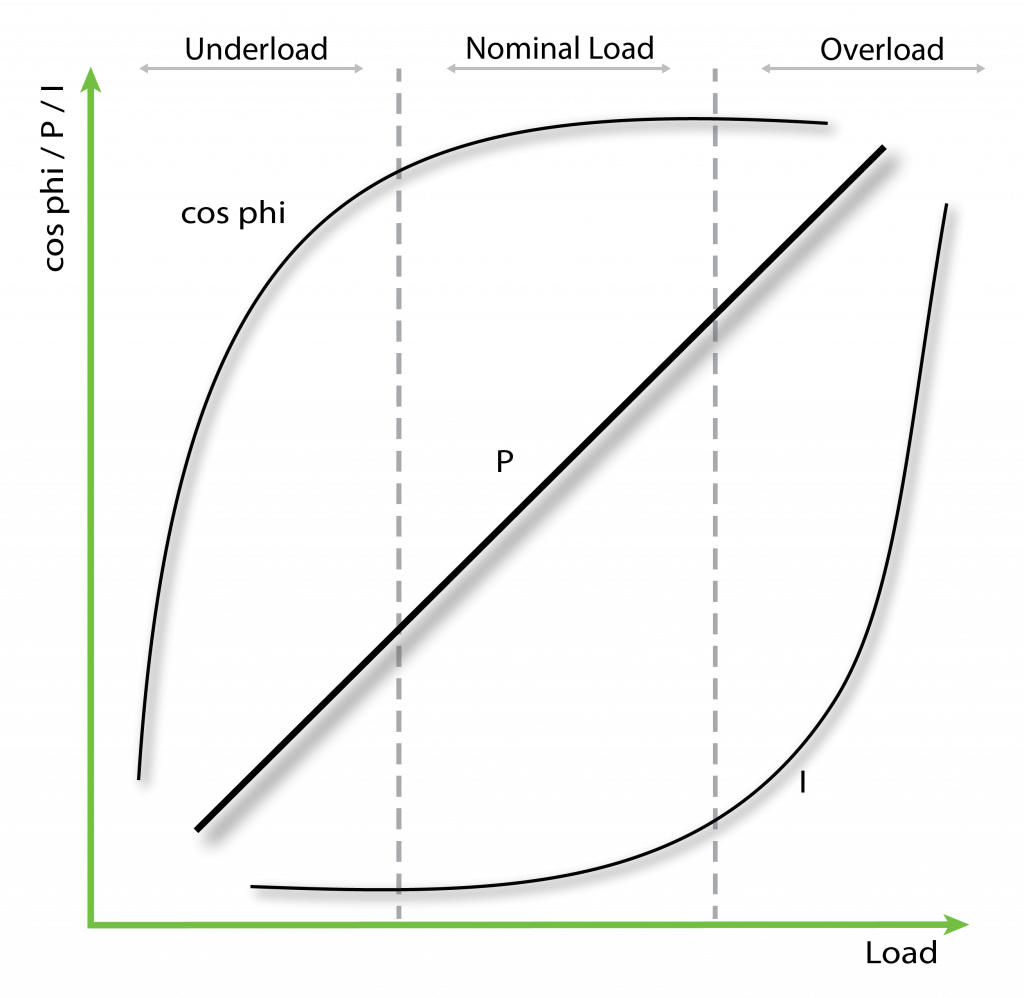

- In an underload range the current does not reduce in a linear manner with the load but instead remains relatively high due to the necessary magnetisation current. Therefore, no relevant correlation exists between current and load.

- The current is dependent on the supply voltage. An undervoltage condition with a constant load can result in an increased current draw. This therefore eliminates monitoring the pure active current too.

Thus, monitoring pure current is only applicable in extreme operating conditions, such as a drive blockage, because the current rises dramatically in such cases.

Power monitoring systems with power factor measurement (cos φ): The power factor cos φ is the cosine of the phase shift angle between the current drawn and the voltage applied. In electrical motors this is dependent on the loading and theoretically equals 1 in an ideal case. However, due to induction it effectively lies within a range of 0.85 to 0.95 with a nominal load.

In an underload range, the cos φ monitor is extremely significant because the proportion of losses at a lower load increases dramatically and results in a cos φ of up to <0.5 in an idle state. This is not applicable around the zero point and in an overload range because load changes only result in minimal changes to the phase shift angle.

Power monitoring systems with effective power measurements: The effective power measurement facilitates obtaining the most precise feedback regarding the state of an electrical motor because the effective power is proportional to the shaft power. A direct correlation exists between the effective power supplied and the motor loading (torque with constant rotational speed) across the entire working range.

Examples for power monitor-usage:

- Agitators

- Crushers

- Grinders

- Shredders

- Compactors

- Ventilation Units

- Machinery Tools

- Conveyor Systems

- Screening Machinery

- Bridge and Portal Cranes

- Centrifugal and Piston Pumps

Aim Dynamics is proud to carry a complete line of power meters including the Tele Haase power meters reviewed in this blog. Found here on the new Aim Dynamics website.