Rogowski coils are used in many industries to accurately measure alternating current(AC). They offer more flexibility, accuracy, and a nonintrusive method of reading alternative currents.

Let's dive to learn more about where and how you can use these Rogowski coils.

Mainly, Rogowski coils are helpful in:

- Precision welding systems

- Arc melting furnaces

- Electromagnetic launchers

Understanding Rogowski Coils

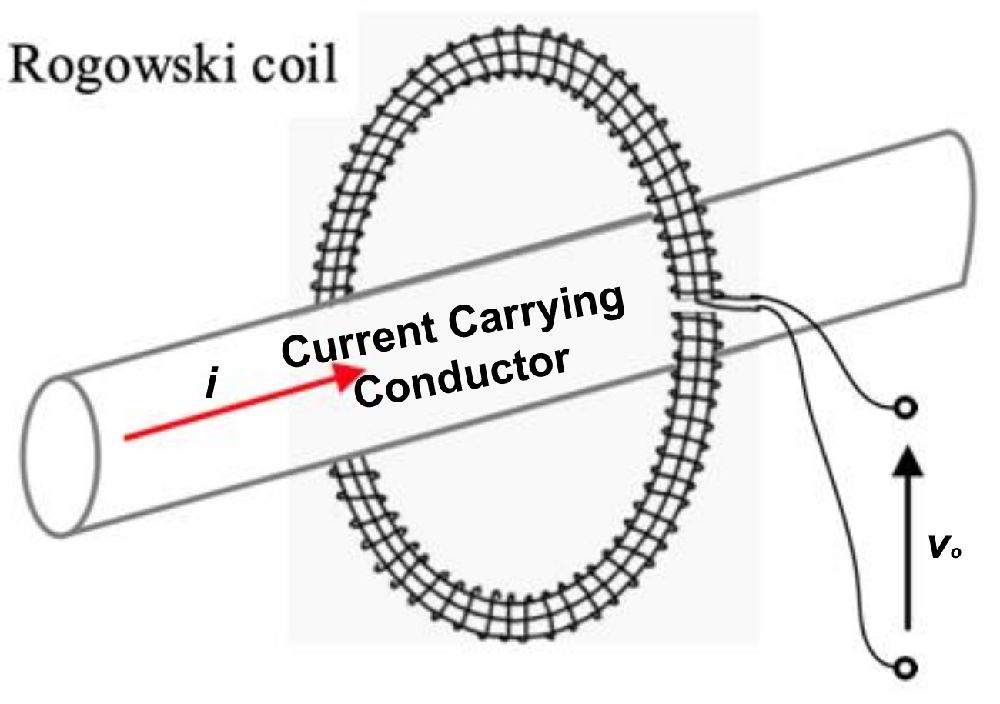

At their core, Rogowski coils are sensors designed to measure AC without direct contact with the conductor. Their construction involves winding a coil around a conductor, which generates a voltage proportional to the current rate of change. This unique design eliminates the need for a magnetic core, making Rogowski coils lightweight, flexible, and easy to install.

How They Work:

- Nonintrusive Measurement: The coil detects the magnetic field produced by the AC, providing an indirect yet precise measurement.

- Flexible Design: Their flexibility allows them to wrap around conductors of varying sizes, making them adaptable for different applications.

- High-Frequency Accuracy: Rogowski coils excel at measuring high-frequency currents, providing reliable data in demanding environments.

Applications of Rogowski Coils

Rogowski Coils finds applications in several fields due to their versatility and precision:

- Precision Welding Systems: In welding systems, precise current monitoring is crucial for maintaining quality. Rogowski coils ensure the proper current is applied, producing solid and reliable welds.

- Arc Melting Furnaces: These furnaces require intense currents to melt metals. Rogowski coils help monitor and control these currents, ensuring the process runs efficiently and safely.

- Electromagnetic Launchers: Devices like railguns use high currents for operation. Rogowski coils measure these currents, providing essential data for performance optimization.

If you are looking for more Rogowski check out this

Rogowski Coil Sensors in Current Monitoring

One of the standout features of Rogowski coils is their ability to function as Rogowski coil sensors. These sensors are integral in monitoring systems where precise current measurement is needed. For instance, precision welding systems' ability to measure and control current ensures consistent quality and safety. The Rogowski coil sensor's accuracy is unmatched, making it an invaluable tool in industrial settings.

Key Features:

- Rogowski Coil Accuracy: Known for their precision, these coils provide accurate, current measurements, even in fluctuating conditions. This accuracy is vital in processes where even a minor deviation can lead to significant issues.

- Current Monitoring in Precision Welding Systems: Rogowski coils in precision welding allow for exact control over welding parameters, improving efficiency and quality.

- Arc Melting Furnaces: In these furnaces, Rogowski coils are used to monitor the large currents required for metal melting, ensuring safe and effective operation.

Rogowski Coil as a Current Transformer

The Rogowski Coil Current Transformer (RCCT) is another common application of this technology. Unlike conventional transformers, RCCTs offer numerous advantages:

- Versatility: They can be used in various applications without the need for different transformers for different current ranges.

- Safety: The non-contact nature of Rogowski coils ensures they are safe to use around live conductors.

- Flexibility: Their design allows easy installation and maintenance, even in challenging environments.

Measuring Alternating Current with Rogowski Coils

Rogowski coils are explicitly designed to measure alternating current (AC). This feature makes them ideal for applications that require precise current measurement, such as:

- Electromagnetic Launchers: Rogowski coils are used in these systems to ensure the accurate delivery of high currents, which is crucial for performance and safety.

- Arc Melting Furnaces: They measure the alternating currents required for melting metals, providing real-time data for process control.

- Measuring Alternating Current in General: Their ability to handle high-frequency AC makes them suitable for various industrial applications, from small-scale electronic devices to large-scale industrial machinery.

Rogowski Coil Accuracy and Its Importance

One of the Rogowski coil's most significant benefits is its accuracy. This accuracy ensures that even the slightest variations in current can be detected and adjusted, preventing potential issues in sensitive applications. This accuracy translates into better product quality and process efficiency in industries where precision is paramount, such as electronics manufacturing or high-frequency welding.

Current Monitoring in Precision Welding Systems

Rogowski coils play a critical role in precision welding systems. Current monitoring ensures that the electrical parameters are precisely controlled, leading to stronger and more reliable welds. The coil's accuracy and ability to measure high-frequency currents make it the preferred choice for this application.

Electromagnetic Launchers and Arc Melting Furnaces

Similarly, in arc melting furnaces and electromagnetic launchers, the need for precise current measurement is paramount. Rogowski coils provide the necessary data to control these systems effectively, ensuring safety and performance.

FAQs about Rogowski Coils

What industries commonly use Rogowski coils?

Rogowski coils are commonly used in welding, metal melting, power distribution, and electromagnetic systems. Their accuracy and flexibility make them suitable for a wide range of applications.

How do Rogowski coils compare to traditional transformers?

Rogowski coils offer several advantages over traditional transformers, including flexibility, nonintrusive measurement, and high-frequency accuracy. They are often more adaptable and more accessible to install in various settings.

Can Rogowski coils be used in harsh environments?

Yes, Rogowski coils can be designed to withstand harsh environments, including high temperatures and corrosive conditions. Protective casings and materials ensure durability and reliability.

Why are Rogowski coils preferred for high-frequency applications?

Their design allows for precise measurement of high-frequency currents, making them ideal for high-frequency accuracy and reliability applications.

Where can I purchase reliable Rogowski coils?

You can purchase reliable Rogowski coils from trusted suppliers like Aim Dynamics, which is known for its quality and customer service.

Conclusion

Rogowski coils are versatile, accurate, and essential for industries requiring precise current measurements. Their applications in precision welding systems, arc melting furnaces, and electromagnetic launchers demonstrate their importance in modern industrial processes. With their flexibility and high-frequency accuracy, Rogowski coils offer an unparalleled solution for current monitoring.

For high-quality Rogowski coils tailored to your needs, consider Aim Dynamics. Our products are designed to meet the demands of various industries, providing accuracy, reliability, and ease of use. Visit our website or contact us today to find the right Rogowski coil solution for your application.

You Might Also Like: What Are The Applications of Rogowski Coil?